"Exploring Modular Home Construction Methods: A Comprehensive Overview"

Modular homes represent a growing segment of the housing market, offering an alternative approach to traditional construction. These factory-built structures are assembled in controlled environments before being transported to their final locations. Understanding how modular homes are constructed, the methods involved, and the structural principles behind them can help prospective homeowners make informed decisions about this increasingly popular housing option.

Modular construction has evolved significantly over recent decades, transforming from basic prefabricated units into sophisticated residential solutions. The process involves creating sections or modules of a home in a manufacturing facility, where quality control measures and standardized procedures ensure consistency. Once completed, these modules are transported to the building site and assembled on a permanent foundation. This method differs fundamentally from traditional stick-built construction, where all building activities occur on-site and are subject to weather delays and variable site conditions.

The controlled factory environment provides several advantages during the construction phase. Workers have access to specialized equipment, materials are stored in optimal conditions, and assembly follows precise blueprints without weather-related interruptions. Each module undergoes rigorous inspections at various stages of production, ensuring compliance with building codes and quality standards. The modules typically include electrical wiring, plumbing, interior finishes, and sometimes even fixtures and appliances before leaving the factory.

What Are Modular Homes and How Do They Differ?

Modular homes are permanent residential structures built in sections at a manufacturing facility and then transported to a prepared site for assembly. Unlike mobile homes or manufactured housing, modular homes must comply with the same local, regional, and national building codes as site-built homes. They are constructed on a permanent foundation and cannot be moved once assembled. The term “modular” refers to the construction method rather than the quality or permanence of the structure.

These homes consist of multiple sections called modules, which are typically built as three-dimensional units complete with walls, floors, and ceilings. The modules are constructed to withstand transportation stresses, often making them structurally stronger than conventional homes. Once delivered to the site, modules are placed on the foundation using cranes and secured together. Skilled contractors then complete the finishing work, including connecting utilities, sealing joints between modules, and adding any site-built components such as garages or porches.

Understanding the Construction Process Step by Step

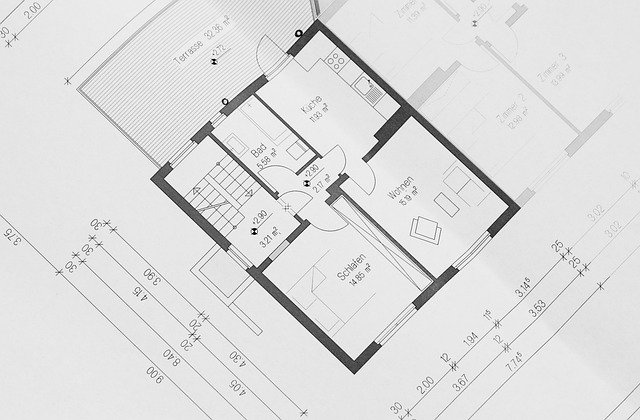

The modular home construction process begins with design and planning. Buyers work with manufacturers to select floor plans, customize layouts, and choose finishes. Once the design is finalized, the manufacturing phase begins in the factory. Construction teams build each module on assembly lines, with different stations handling framing, electrical work, plumbing, insulation, and interior finishing. This parallel processing significantly reduces construction time compared to traditional methods.

Simultaneously, site preparation occurs at the home’s final location. This includes excavation, foundation construction, and utility connections. The foundation must be completed and inspected before module delivery. When modules are ready, they are transported on flatbed trucks to the site. Delivery and assembly typically occur within one or two days, though finishing work may take several additional weeks. This includes connecting modules, completing exterior siding where sections join, installing stairs, and finishing interior details at module seams.

How Modular Home Structures Are Engineered

Modular homes utilize engineering principles that account for both permanent installation and transportation stresses. The structural framework typically consists of wood or steel framing, similar to conventional construction. However, modules must be reinforced to handle lifting and transport without damage. This often results in stronger overall construction with additional bracing and support elements.

Floor systems in modular homes are engineered to support not only the living loads but also the stresses of being lifted and moved. Wall systems include standard framing with insulation, vapor barriers, and interior and exterior finishes. Roof structures may be built as part of the modules or constructed on-site, depending on the design and transportation constraints. Marriage walls, where two modules join, require special attention to ensure structural integrity and proper sealing against weather infiltration.

Exploring the Foundation and Site Requirements

Modular homes require permanent foundations similar to traditional homes. Common foundation types include full basements, crawl spaces, and slab-on-grade foundations. The choice depends on local building codes, soil conditions, climate, and homeowner preferences. The foundation must be precisely constructed because modules are built to exact specifications with minimal tolerance for adjustment.

Site preparation involves clearing and grading the land, ensuring proper drainage, and installing utility connections. Local building departments typically require foundation inspections before module placement. Access to the site must accommodate large trucks and cranes, which may be challenging in areas with narrow roads or dense tree coverage. Proper site planning ensures smooth delivery and assembly while minimizing potential complications.

What Materials and Techniques Are Used?

Modular home construction employs standard building materials including dimensional lumber, engineered wood products, steel framing components, drywall, insulation, and conventional roofing and siding materials. The difference lies in how these materials are assembled. Factory construction allows for precise cutting, consistent assembly, and protection from weather during the building process.

Manufacturers use computer-aided design and automated cutting equipment to ensure accuracy and minimize waste. Quality control procedures include inspections at multiple stages, moisture content testing for lumber, and verification of electrical and plumbing installations. Many factories have achieved certifications for quality management systems, demonstrating commitment to consistent production standards. Advanced techniques such as panelized wall systems and pre-assembled components further streamline the manufacturing process.

Comparing Costs and Value Considerations

The cost of modular homes varies based on size, design complexity, finishes, and location. Generally, modular construction can offer cost advantages over traditional building due to reduced labor costs, bulk material purchasing, and shorter construction timelines. However, transportation costs, crane rental, and finishing work must be factored into the total project budget. Site preparation and foundation costs are comparable to traditional construction.

| Cost Component | Estimation Range | Notes |

|---|---|---|

| Base Module Cost | €800 - €1,500 per square meter | Varies with finishes and complexity |

| Site Preparation | €5,000 - €20,000 | Depends on land conditions |

| Foundation | €8,000 - €30,000 | Type and size dependent |

| Delivery and Assembly | €3,000 - €10,000 | Distance and access factors |

| Finishing Work | €5,000 - €15,000 | Connections and final details |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Financing modular homes follows similar processes to traditional mortgages, though some lenders may have specific requirements or programs for factory-built housing. Appraisals consider the completed home value rather than the construction method. Long-term value retention for quality modular homes is comparable to site-built homes when properly maintained and situated on owned land.

Modular home construction represents a viable alternative to traditional building methods, offering potential advantages in construction speed, quality control, and cost efficiency. Understanding the construction process, structural principles, and cost considerations enables informed decision-making for those considering this housing option. As manufacturing techniques continue to advance and building codes evolve, modular construction is likely to play an increasingly significant role in addressing housing needs.