"Exploring Modular Home Construction Methods: A Comprehensive Overview"

Modular home construction represents a shift in how residential buildings are designed and assembled. Unlike traditional on-site building methods, modular construction involves creating sections of a home in a controlled factory environment before transporting them to the final location for assembly. This approach combines precision engineering with efficient production techniques, offering an alternative pathway to homeownership that appeals to English-speaking residents in France seeking innovative housing solutions.

The construction industry has evolved significantly over recent decades, and modular home building stands as one of the most notable developments in residential architecture. These homes are constructed using factory-based processes that differ substantially from conventional building methods, yet result in structures that meet the same safety and quality standards as traditionally built houses.

How Does Modular Home Construction Actually Work

Modular home construction begins in a manufacturing facility where individual sections, called modules, are built simultaneously. Each module represents a portion of the final home, complete with interior finishes, electrical systems, plumbing, and structural components. Factory workers assemble walls, install flooring, add insulation, and complete much of the interior work while the modules remain in the controlled environment. This parallel production process significantly reduces overall construction timelines compared to sequential on-site building. Once modules are completed, they undergo quality inspections before being transported via specialized trucks to the building site. At the destination, cranes lift and position each module onto a prepared foundation, where skilled technicians connect the sections, seal joints, and complete final installations. The entire assembly process at the site typically takes only a few days to a few weeks, depending on the home’s complexity.

What Makes Modular Home Structures Different from Traditional Buildings

The fundamental distinction lies in where construction occurs rather than the final product quality. Modular homes must be engineered to withstand transportation stresses, which often means they are built with additional structural reinforcement compared to site-built homes. Each module is constructed as a self-supporting unit capable of being moved without compromising integrity. Factory construction allows for precise measurements and consistent quality control, as work occurs indoors without weather-related delays or material degradation from exposure to elements. Building codes and regulations apply equally to modular and traditional homes, ensuring that completed modular structures meet all local safety, electrical, plumbing, and structural requirements. The modules arrive at the site typically 70 to 90 percent complete, with remaining work focused on connecting utilities, finishing exterior elements, and completing any customizations specific to the site.

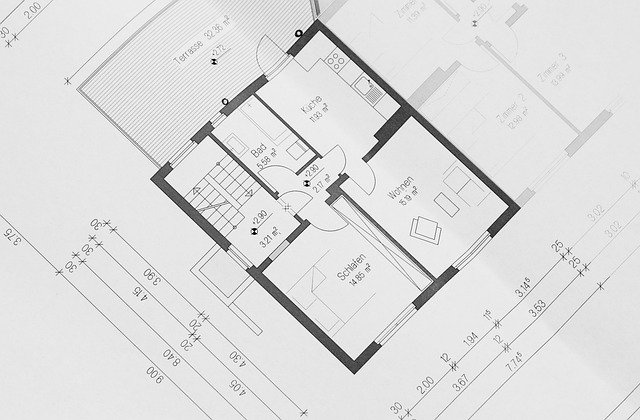

Understanding the Basic Components of Modular Home Systems

A modular home consists of several key structural elements that work together to create a complete residence. The foundation, whether a basement, crawl space, or slab, is prepared on-site before module delivery and must meet local building codes. Floor systems within each module include joists, subflooring, and often finished flooring materials installed at the factory. Wall assemblies incorporate framing, insulation, interior finishes like drywall, and sometimes exterior cladding, depending on the manufacturer’s process. Roof systems may be completed at the factory or finished on-site, depending on transportation constraints and design specifications. Electrical and plumbing systems are roughed in or fully installed within modules, with connection points designed for easy joining during assembly. HVAC systems are typically installed partially in the factory and completed on-site to ensure proper integration across all modules. Windows and doors are usually installed at the factory, arriving ready for final sealing and trim work. The marriage wall, where two modules meet, requires special attention during assembly to ensure structural continuity and weatherproofing.

What Are the Steps Involved in Modular Home Production

The production process follows a systematic sequence that maximizes efficiency and quality. Initial design and planning involve working with architects or using pre-designed floor plans that accommodate modular construction constraints. Engineering specifications are developed to ensure modules can withstand transportation and meet all building codes. Factory production begins with framing on assembly lines, where walls, floors, and roof components are constructed. As modules move through the production facility, different teams install specific systems—plumbers rough in water and waste lines, electricians run wiring and install boxes, and insulation specialists add thermal barriers. Interior finishers install drywall, cabinetry, fixtures, and flooring while the module remains in the climate-controlled factory. Quality control inspections occur at multiple stages, checking structural integrity, system installations, and finish quality. Once approved, modules are wrapped in protective materials and loaded onto transport vehicles. Site preparation occurs simultaneously with factory production, ensuring the foundation is ready when modules arrive. On-site assembly involves crane placement of modules, structural connection of sections, completion of utility hookups, and finishing work that ties all modules into a cohesive home.

Comparing Modular Construction Approaches and Providers

Several companies specialize in modular home manufacturing, each offering different construction approaches and features. Understanding these options helps potential buyers make informed decisions.

| Provider Type | Construction Approach | Key Features |

|---|---|---|

| Full-Service Manufacturers | Complete design through delivery | Turnkey solutions, design assistance, transportation coordination |

| Custom Modular Builders | Tailored designs with factory efficiency | Architectural flexibility, premium materials, personalized layouts |

| Production Home Manufacturers | Standardized floor plans at scale | Cost efficiency, proven designs, shorter lead times |

| Hybrid Builders | Combination of modular and site-built elements | Design versatility, site-specific customization, mixed construction methods |

What Considerations Apply to Modular Home Construction in France

For English-speaking residents in France considering modular homes, several factors warrant attention. French building regulations, including RT 2012 energy standards or newer RE 2020 requirements, apply to all residential construction regardless of method. Modular homes must comply with these thermal performance and environmental standards. Local planning permissions and building permits follow the same processes as traditional construction, requiring submission of plans to local authorities. Transportation logistics within France may differ from other countries, particularly regarding route planning for oversized loads and crane access at rural or urban sites. Some regions in France have embraced modular construction more readily than others, with varying levels of contractor experience in assembly and finishing work. Language considerations may arise when working with international modular manufacturers, making it important to ensure clear communication throughout the design and construction process. Financing for modular homes in France typically follows similar pathways as traditional construction, though some lenders may require additional documentation about the manufacturing process and structural certifications.

Modular home construction represents a viable alternative to traditional building methods, offering efficiency, quality control, and design flexibility. Understanding how these homes are manufactured, transported, and assembled provides valuable insight for anyone considering this construction approach. The factory-based process, combined with on-site completion, creates homes that meet rigorous standards while potentially reducing construction timelines and providing consistent quality outcomes.